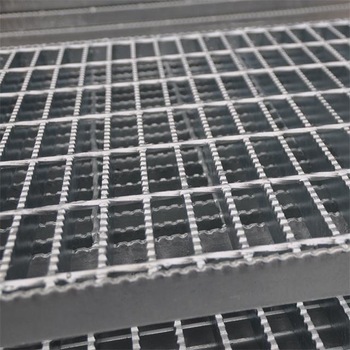

Umklamo wenqubo wei-steel gratingiwukuhlela imininingwane yejiyomethri yeshidi ngokuvumelana nobukhulu bepuleti lokuqala.I-steel grating ikhiqizwa nge-bearing bar kanye ne-cross bar. Umgomo omkhulu uwukwenza uhlelo lokusika lucabangele izinga lokusetshenziswa kwezinto kanye nokusebenza kahle kokukhiqiza okuphezulu. Izimiso zokuqhathanisa inqubo ye-steel grating ikakhulukazi ihlanganisa izici ezilandelayo:

1. Konkeiizinsimbi zensimbingosayizi wepuleti ogcwele noma ngaphezulu kukasayizi wepuleti ogcwele afaniswa ngokukhethayo ngokushoi ubude. Usayizi ofanayo mncane ngangokunokwenzeka futhi umfaniswano, futhi ububanzi bobude bulawulwa ngaphakathi kwamamitha angu-5-7.

2. Inombolo encane yamabhodi emincane ingahlelwa ngokulandelana kobubanzi ukusuka kokuncane kuya kokuncane noma okuncane kuya enkulu, bese ingahlanganiswa ndawonye ngokuhambisana ngokuvumelana nobude.

3. Lapho ububanzi buchichima, sebenzisa ibha yesiphambano yezinto ezingavuthiwe ukuze wenze inqubo ye-welding yokugoqa, futhi ungashisi ipuleti ngokuhlukana.

4. Umshini wokushisela we-double-bar ucindezela futhi ushise ama-cross bar angu-2 isikhathi ngasinye, futhi inombolo eyinqaba ayikwazi ukuba khona.

5. Ukumatanisa phakathi kwebhodi nebhodi kufanele kugcine ubukhulu bomgwaqo wokusaha. Uma kungenele,iI-cross bar idinga ukukhishwa.

6. Iqoqo lemidwebo lidinga ukuhlukaniswa ngokuqinile. Uma imidwebo eminingi idlula ama-square metres angu-200, le midwebo idinga ukufaniswa ndawonye. Uma ubukhulu bungaphansi kwamamitha-skwele angama-200, bungabhekwa njengokufaniswa nemidwebo emincane

7.Ukuze uthole i-grating yensimbi emise okukhethekile, kuyadingeka ukucabangela ukuqaqa kanye nokuhlanganisa kwezinqe ukuze kuzuzwe ukonga impahla.

8. Kumapuleti anesikhala sensimbi esiyisicaba esingu-60 mm, iziqeshana zekama ezinesikhala esingu-30 mm zingasetshenziselwa ukukhiqiza impahla eluhlaza.

Isikhathi sokuthumela: Jul-21-2022